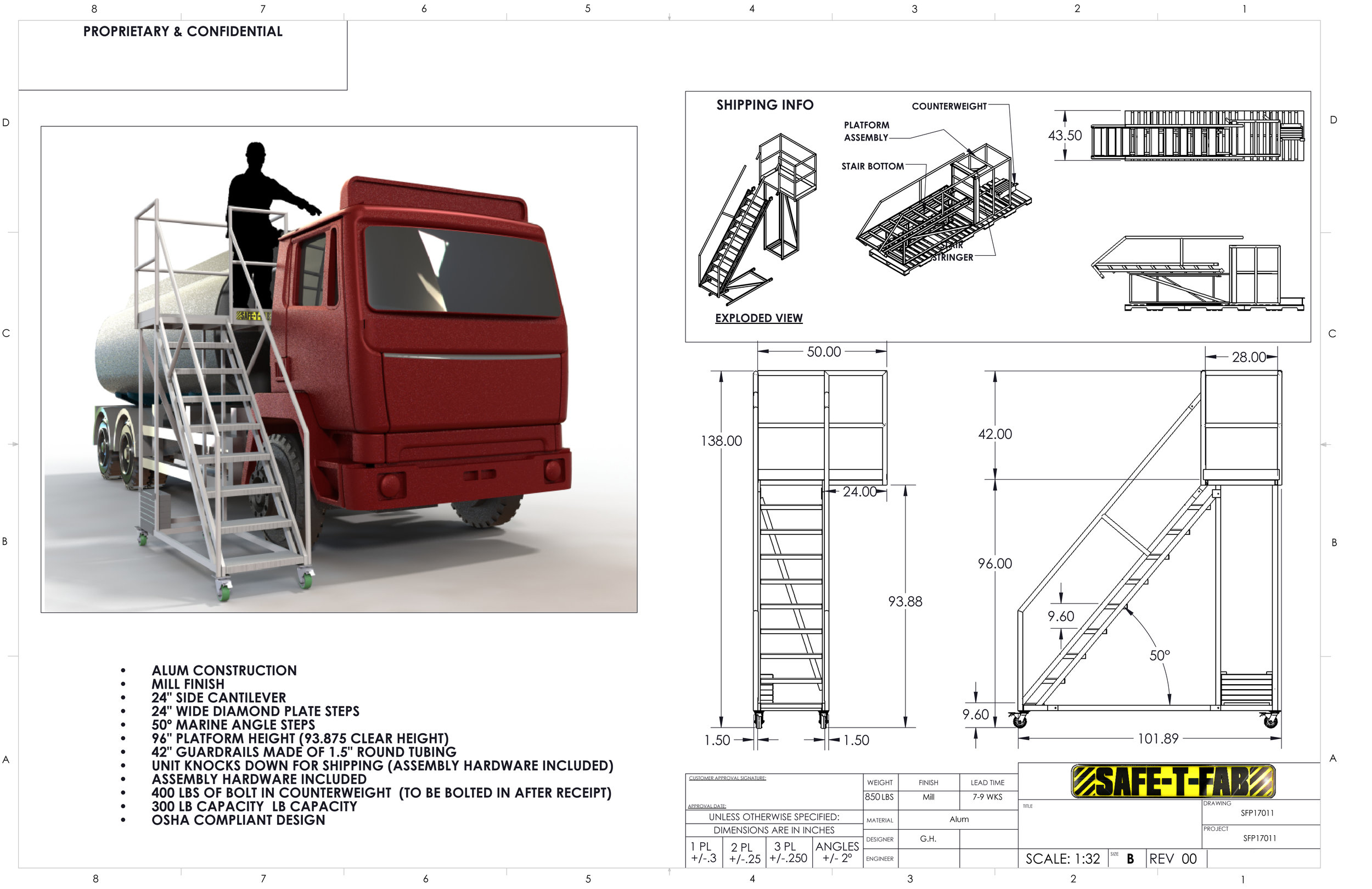

Truck Access Side Cantilever

The challenges for this case study can be summed up into 2 basic categories. "Ergonomics" and "lack of floor space". The customer modifies truck various chassis for specialized use, which requires their employees to get out, and over obstructions in order to get to their scope of work. This is an obvious application for a "cantilever" ladders, but it wasn't that simple. Tight vehicle bays in a multi-bay facility did not allow the space for traditional cantilever ladders. This is where SAFE-T-FAB proposed a unique solution to the customer's problem.

Project evaluation

The SAFE-T-FAB team evaluated the issues at hand for the project, using drawings of the trucks that the customer modifies, ergonomic standards for safe work zones/areas for employees, and photo references of the customer's shop to help us truly understand the space constraints involved. This information, and consistent and fluid communication between SAFE-T-FAB and the customer allowed the design team to develop a suitable solution for proposal.

design proposal

With real estate in the customer's shop at a premium, our team felt it was necessary to address the product in a "parallel" fashion, pulling up next to the work with our product, and then leaning "out over" it. This is called a "side cantilever", and involves the use of counterweight to make sure the center of gravity is in a safe place when the employee is on the platform performing the work. The proposal shown below was part of a multi product design offering, with different products designed to address different applications for the customer.

Final Product

After getting full buy in from the manufacturing crew, management team and safety professionals at the customer site, SAFE-T-FAB went to work on building several different height/sized side cantilever ladders, each with it's own unique purpose and application. Some of the mobile stairs even had a 75 degree marine angle stair, as shown below, to address areas that had very tight floor space constraints. All in all, the project was a big success, allowing the end user to make a vast improvement in the ergonomics and safety for their workers, all while improving the productivity as well. Due to the accurate information the customer provided regarding their products, as you see below, SAFE-T-FAB really nailed how the product would look in use, long before anything was ever built. This is what makes our process one-of-a-kind in this industry.