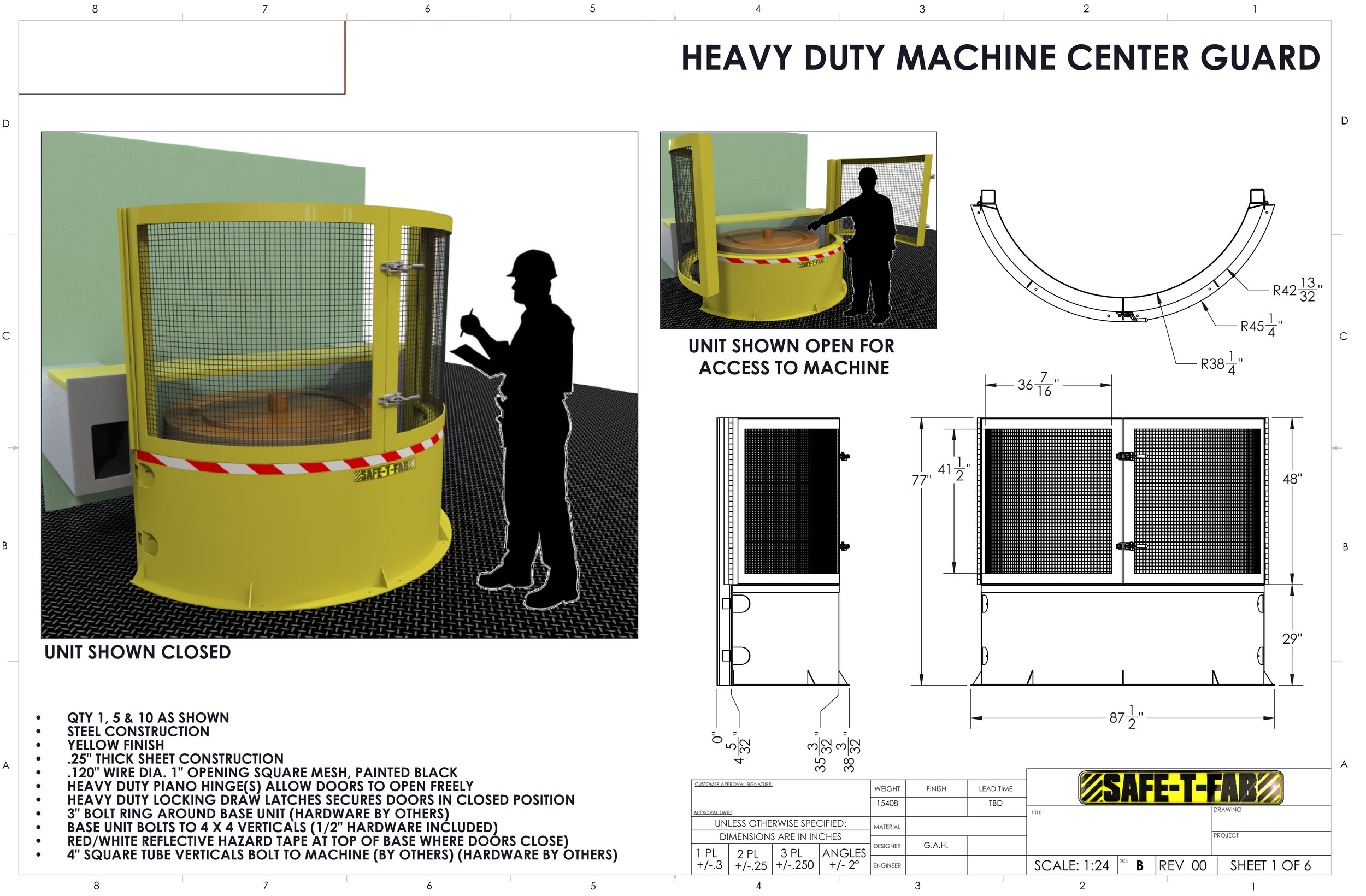

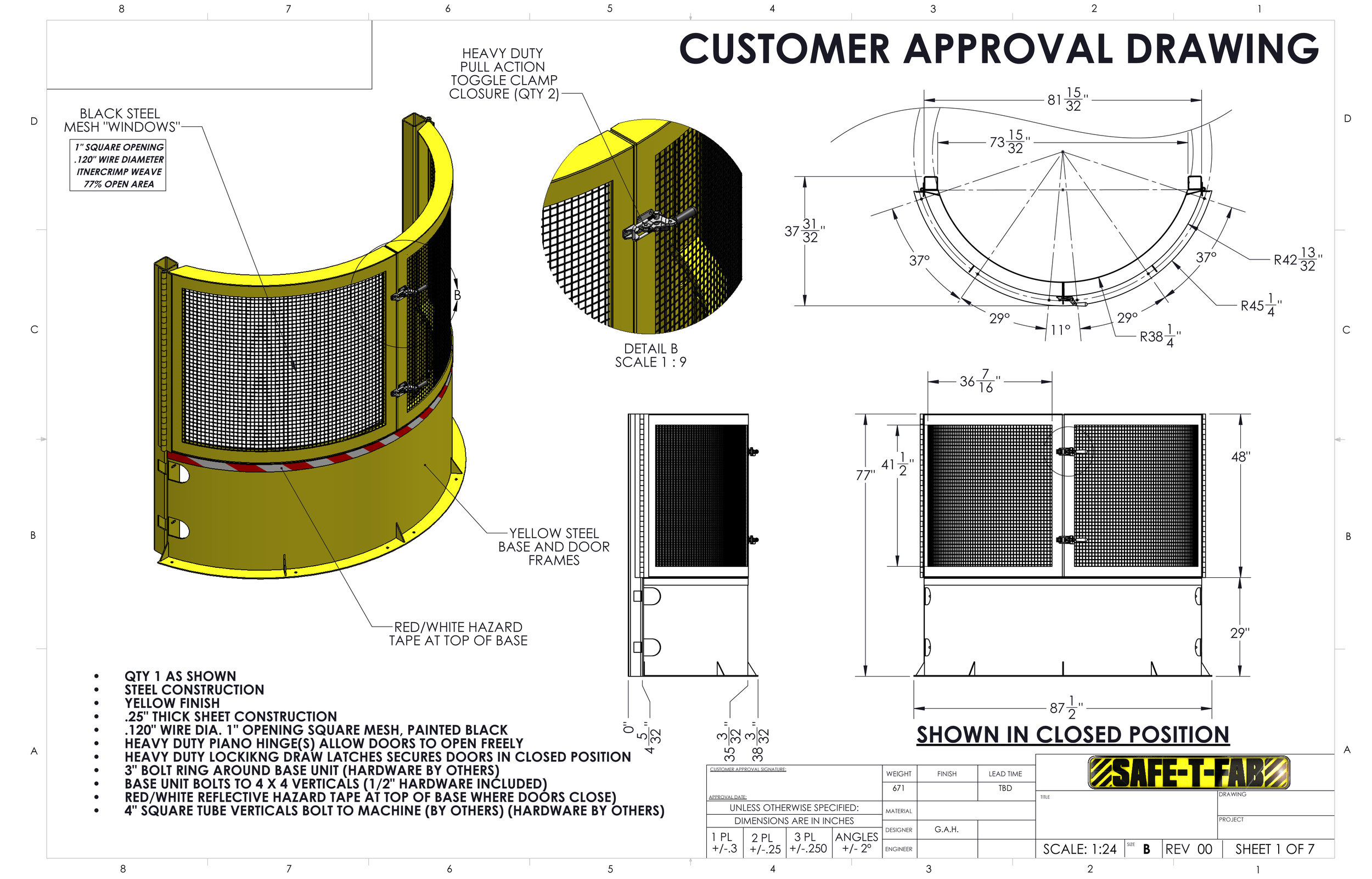

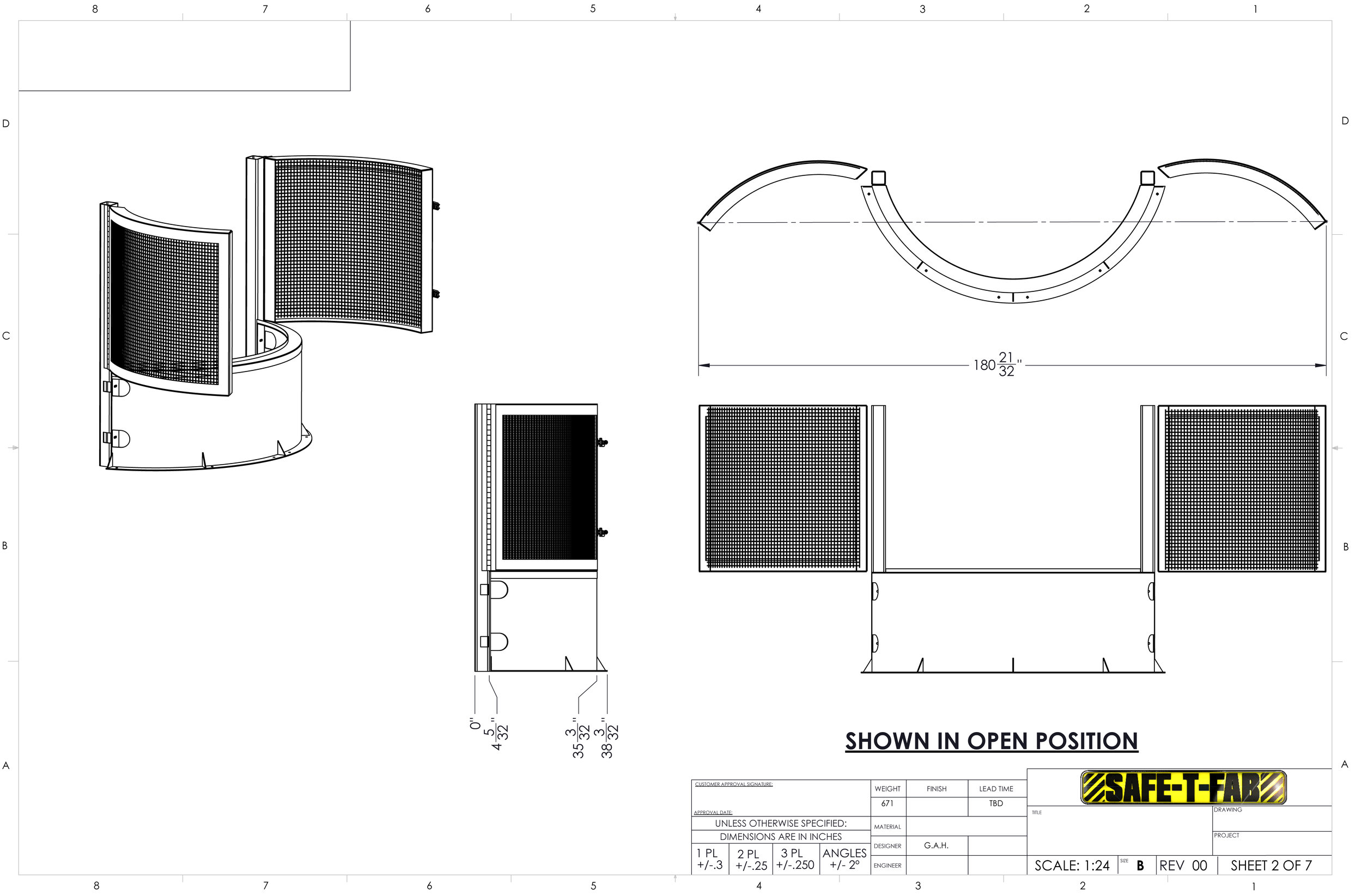

Vertical Mill Machine Guard

For this case study, we look at a project involving Machine Guarding. The customer actually had OEM guarding that came with the equipment, but after a review by OSHA, it had been deemed insufficient and needed upgrading. SAFE-T-FAB was contacted to assist with an improved design and manufacture of the guarding to get their Vertical Mill Centers up to current standards.

Project evaluation

The customer supplied SAFE-T-FAB with some photos of the area they were looking to guard and we met with their safety coordinator to determine the project goals as we moved into the design phase. Several basic dimensional sketches were sent, as well as some basic information on what they were required to improve, and our ideas on how to provide the improvements.

design proposal

The information above was reviewed by our safety team, and a plan was put into action to develop a design to meet the customer's needs, as well as the meet OSHA requirements. As with all of our projects, SAFE-T-FAB provided a comprehensive proposal, to ensure we were capturing every aspect and initiative discussed during our project evaluation.

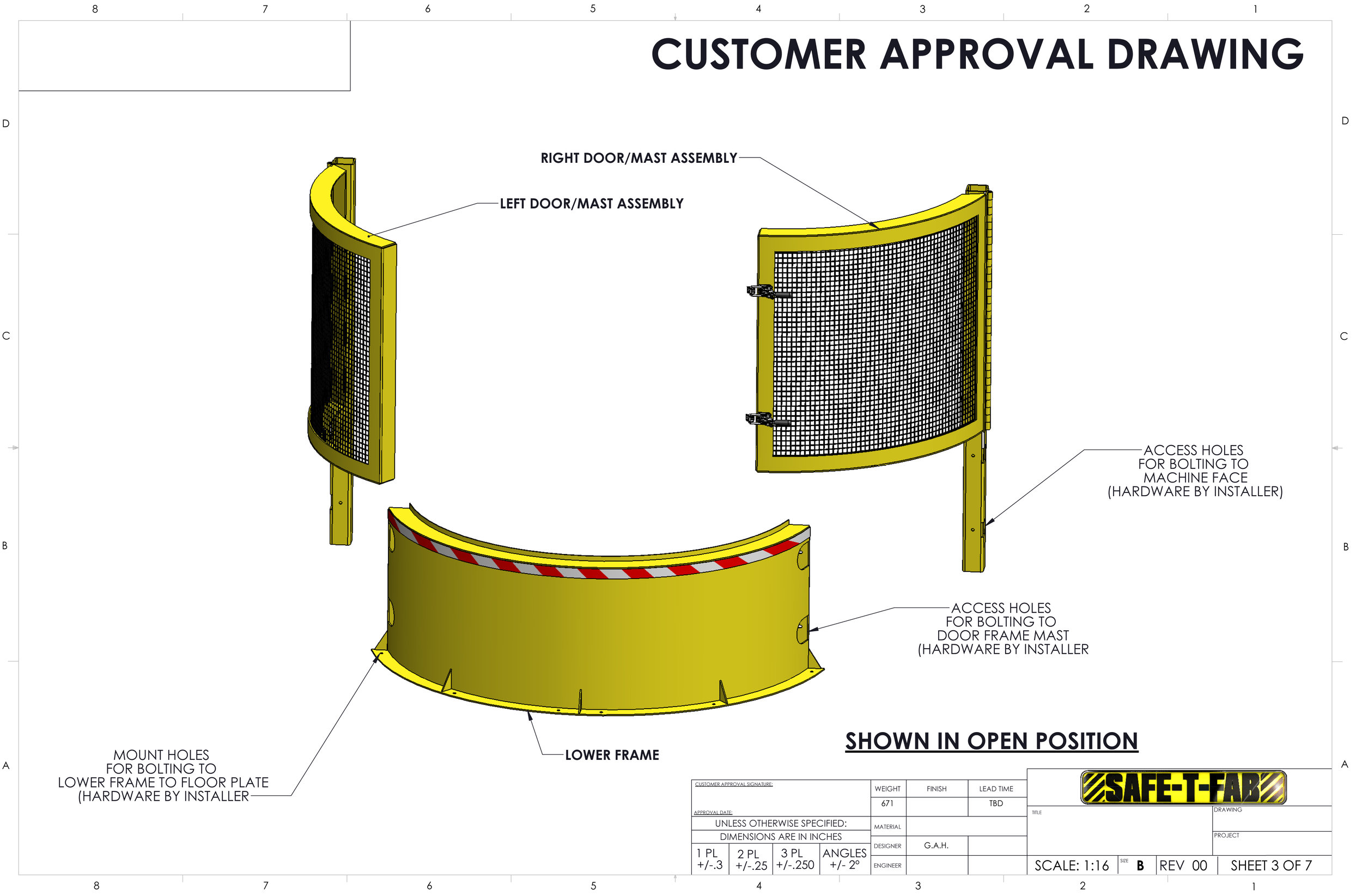

Final Product

Our shop took the finalized item and meticulously worked through the fabrication process, never missing any details or requirements needed to hit the mark. While easy access, upgraded guarding capacity, and a better, tighter fit to the machine were important, aesthetics were a key component on this project as well. SAFE-T-FAB's ability to deliver well built products is never overshadowed by a less than perfect appearance. This made the project a showpiece for both SAFE-T-FAB and the customer.